Concrete bio-polymer secretions/ extrusions

Toolings / Weaving bio-concrete (material expertise)

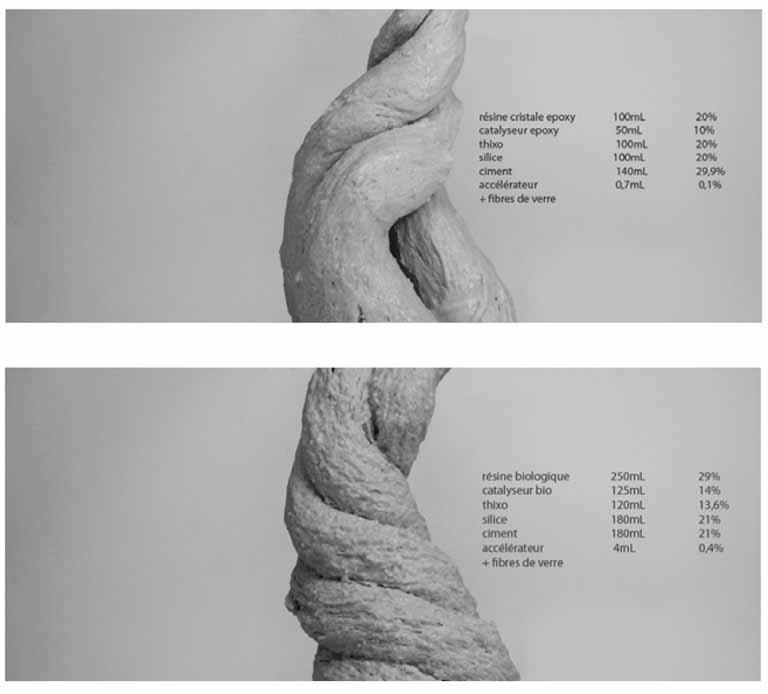

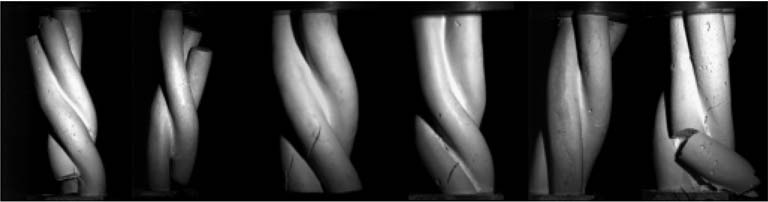

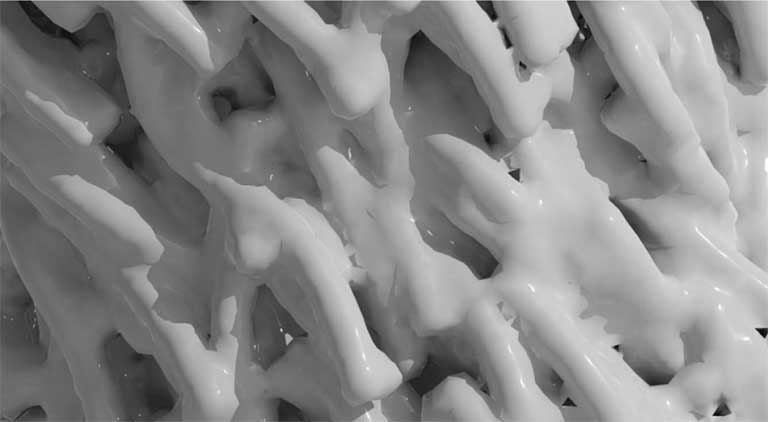

The development of a secretion material whose viscosity and adhesiveness is compatible with the machinist protocol (materials and procedures similar to the contour-crafting system developed with the USC Behrokh Khoshnevis lab for the ″ I′ve heard about ″ project). It’s a sort of polymer concrete, a mixture of biological resin and cement fill. The resin is produced by the agricultural polymer industry. It makes it possible to control the parameters for viscosity, liquidity and polymerization in producing a physical and chemical agglutination as it is secreted. The mechanical appraisal of this material is thus rendered visible (constraints regarding failure due to tension, compression, etc.).

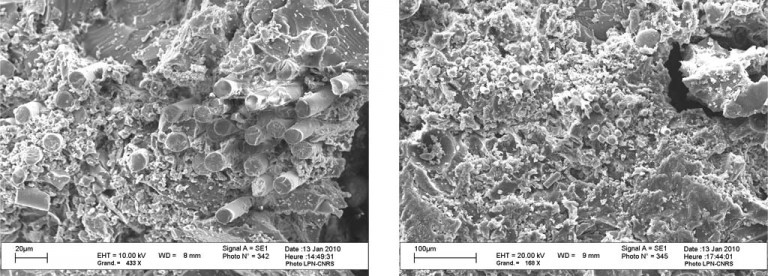

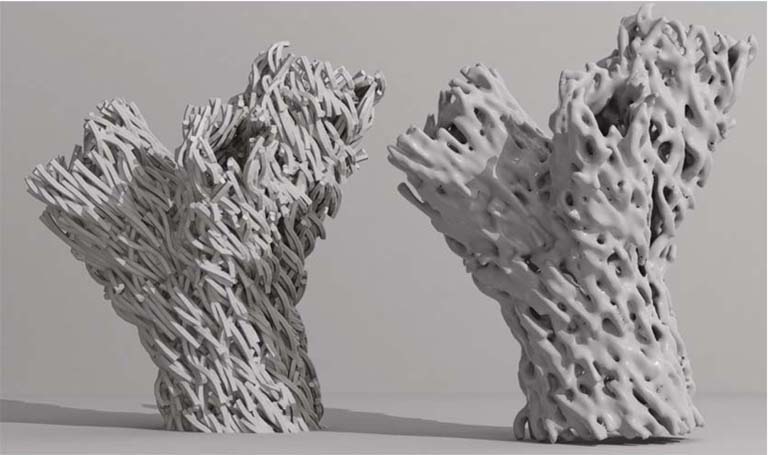

In contrast to computational optimization calculations that produce the trajectories of forces and their volumetric, the ″ hyperlocal brick ″ calculation comes after the braiding algorithm. This generates and induces adhesive areas in order to correspond to the trajectories of the load lines.

Since it is an agricultural product and not made with fossil fuel, this bio-resin is low in CO2 emissions.

| click image for movie |

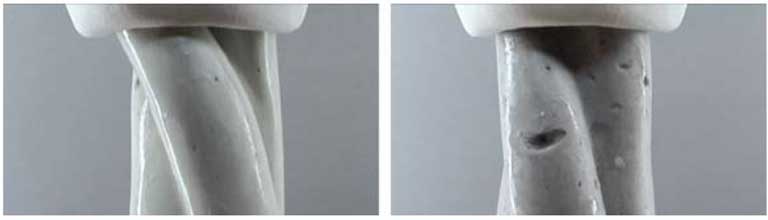

Comparison concrete/bio-concrete

Classic / Concrete / Concrete Polymer

Mix / Cement + water / Resin +Quartz

Manufacturing Time / 28 days / 2-16 hours

Value of compression / 25 Mpa / 3 to 4 times more important

Value of bending by traction / Low / 5 times more important

Resistance to Ph / 6 to 10 / 1 to 14

Coefficient of disposal / 90 / 108 / (Maning Syrup)

Coefficient of abrasion / Higher than 2 / Less than 1 / ( CNR index) ( CNR index)

Leak proofness / Porosity important / Very low porosity of surface

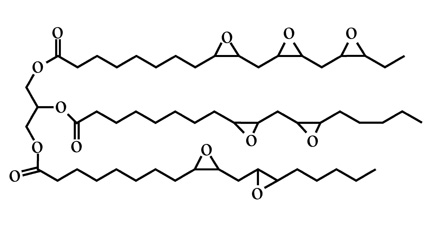

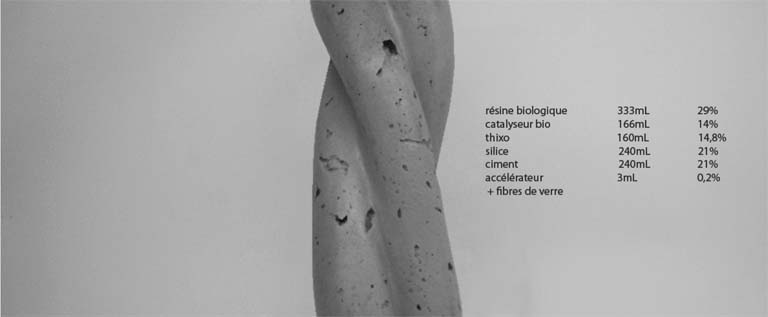

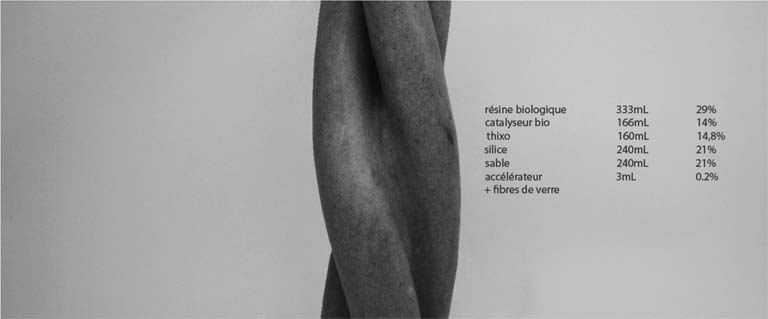

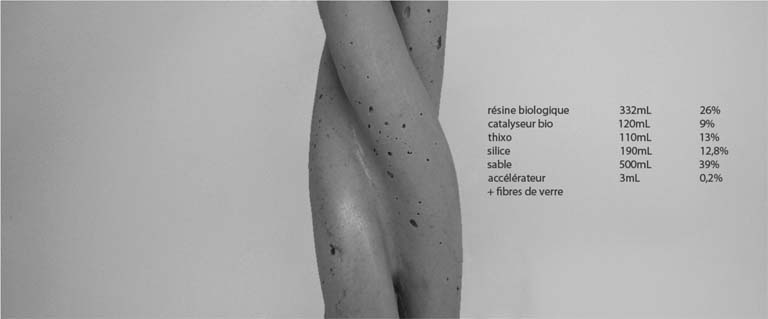

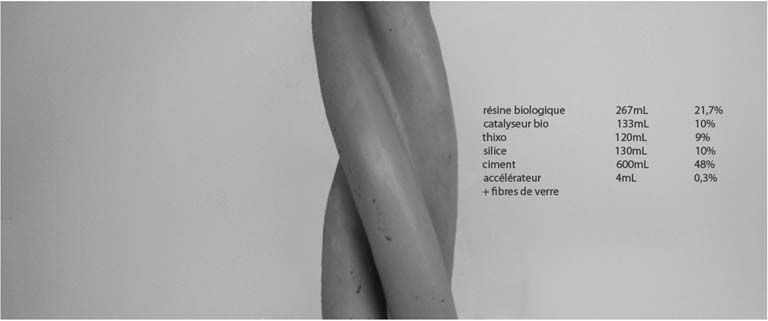

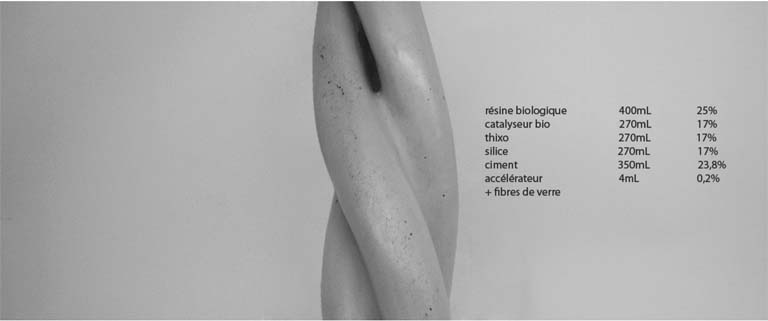

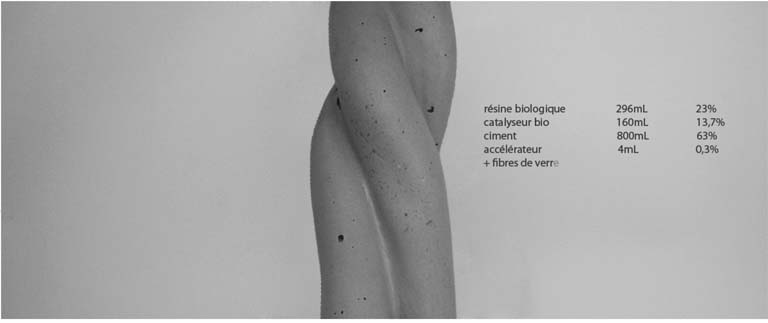

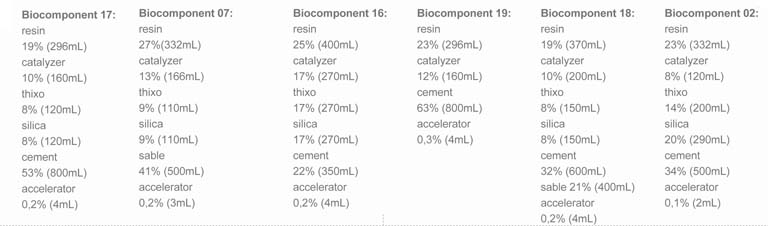

Recipe of the bio-component

Dracowol EP-10/3 P 37

Component A : Bio-epoxy of flax type EP 10/3

Component B : Hardener Paste – mixture of acid and carbonic anhydride

Component C : loads, such as gravel, sand Silica andThixo,

Component D : Cement

Reinforcement: Glass fibers

(A and B: system 2 components resin / hardener)

Viscosity at 23°C: 1445 DIN 53019

Solidification Point: -5°C

Density: 1,084 g/cm^3 DIN EN ISO 3675

Time till completely hard: 28 days to 23°C

Resistance to compression of bio- resin without load: 105 N/mm2

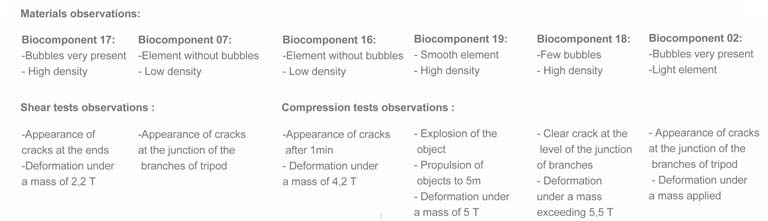

Tests of concrete bio-polymer (mechanical tests – ITKE University of Stuttgart)

| click image for movie |

High Speed Camera \ IDT (www.idtvision.com) Redlake MotionXtra N4color

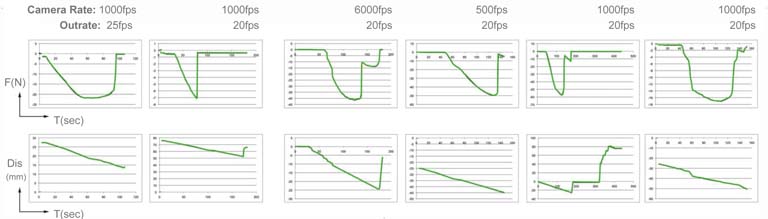

electron microscopic images of bio polymere cement with glas fibers by Simon Vassant at CNRS École Centrale, Paris

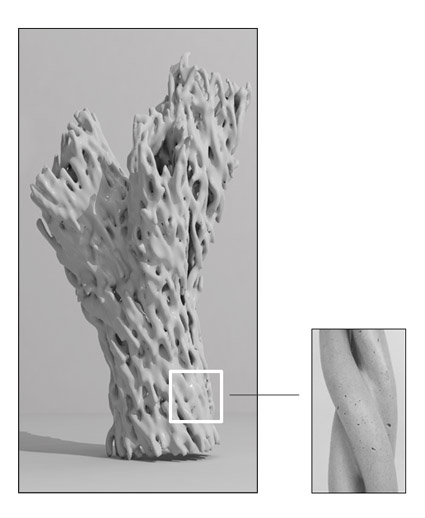

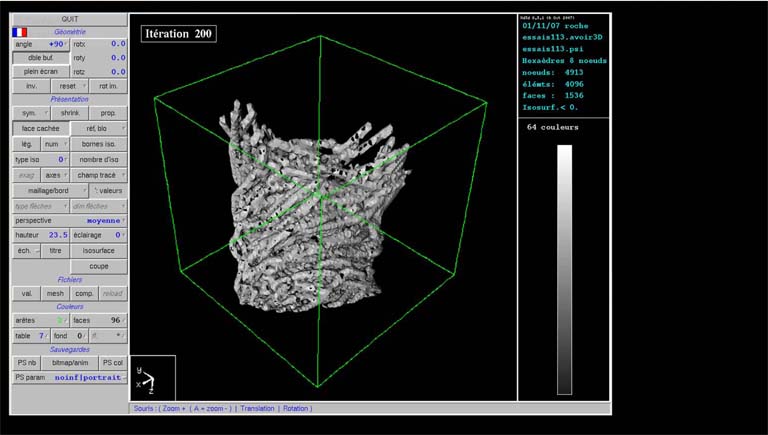

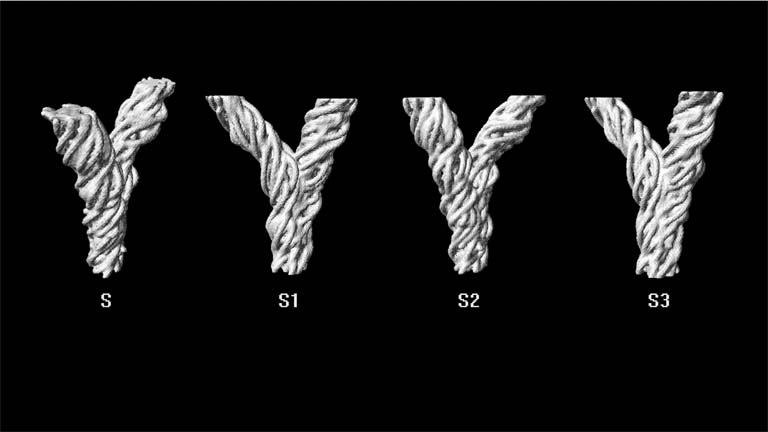

Structural computation of weaving (secretion and coagulation)

Structural computation of weaving

| click image for movie |

Fragment Y (bifurcation), from weaving to coagulation